Here at Mantaro, we offer a full suite of mechanical design services from system integration hardware assembly design to full mechanical product design. We are familiar with working with metals, plastics, composites and other advanced engineering materials. Some specifics include, carbon fiber, carbon fiber filled nylon 3D prints and compression molds, TPU, aluminum, Delrin, as well as many other engineering solution specific materials. Our in-office mechanical Lab allows for rapid prototyping utilizing CNC machining, 3D Printing, sheet metal bending and fabrication, composite prototyping, and more. We use 3D CAD modeling to generate designs rapidly while using thermal and mechanical simulation to validate and generate optimized prototypes for any challenge. Our mechanical engineering team can take challenging problems and bring them to life. The collection of knowledge along with partnering with production specialists allows us to design, develop, and prototype a wide variety of products that are ready to manufacture.

Capabilities

- Custom Enclosures

- Front Panel Design

- Product Packaging

- Mechanical Concept Drawings

- CAD modeling

- Structural Analysis

- Materials Selection

- Thermal Analysis and Modeling

- Fabrication Drawings

Model Shop

- Rapid Prototyping

- CNC Milling

- 3D Printing (SLA, FFF)

- Sheet Metal

- Carbon Fiber composites prototyping

- Aluminum Anodizing

Custom Heatsinks

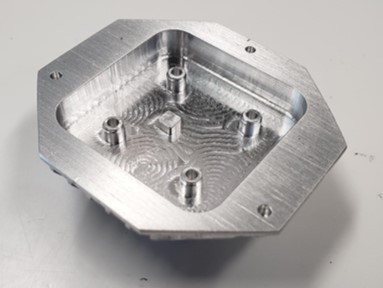

Custom Heatsink for RF Amplifier to mount on UGV

We can design custom heatsinks and fabricate prototypes onsite in our model shop.

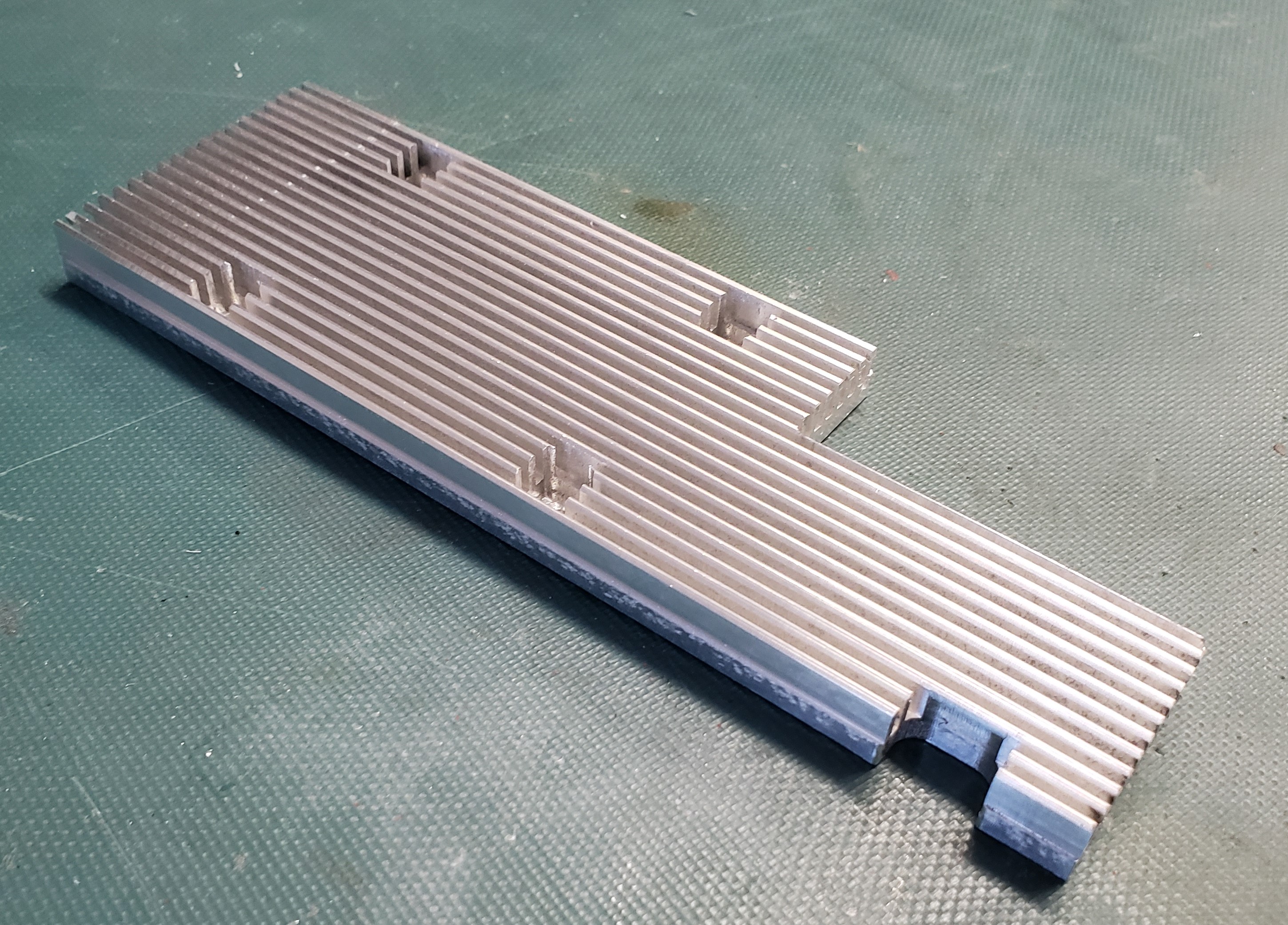

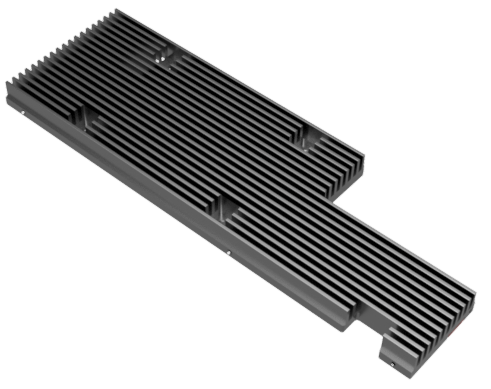

CAD and Photo of Custom Heatsink for FPGA Solution

Design and rapid manufacturing of custom heatsinks for high performance computing solutions such as FPGA boards for satellite ground stations, cryptography solutions, quantum computers, or power supplies.

Custom Front Panel

Front Panel for PCI Card

Design and prototyping of custom front panels.

Custom Enclosures

Manufacturing Test Fixture and Custom Enclosure

Mantaro has developed custom enclosures and test fixtures for a variety of applications including manufacturing and industrial environments. Mantaro's cross-discipline team has experience developing enclosures for vibration, EMI, dust, fluids, and more. Whether it is a small set of units for a custom test fixture or a larger production run Mantaro can develop enclosures and integration to achieve the specific design requirements.

Mantaro understands that every project has specific requirements that depend upon exceptional attention to detail. Mantaro Is able to leverage experience across disciplines and through the entire design process to optimize application-specific designs. Mantaro has experience developing enclosures for a variety of manufacturing and prototyping processes including injection molding, composites, and 3D printing. Our experienceincludes designing chassis and enclosures and working with testing labs to meet design specifications required for MIL-STD 810, IP and package and handling requirements. Mantaro develops and designs for assembly, manufacturing, and material selection to optimize the application chassis or enclosure. Mantaro has relations with distributors and suppliers and many commercial off the shelf hardware suppliers to keep up do date on the most recent and cutting-edge materials and processes available to achieve the application-specific needs.